|

|

PCB

- Printed Circuit Board

Etching

Place the PCB in the etch tank. The etch tank is a tall, thin tank

that contains the etching chemical. Common etching chemicals include

Ferric Chloride and Ammonium Persulfate. The tank also contains a

heater and bubbler. The bubbler pumps air through the tank to

agitate the chemicals to speed up the etching process. Etching

typically requires 3-5 minutes with a fresh, heated solution. TIP

- Ammonium Persulfate is a clear etching chemical that produces

less caustic vapors than Ferric Chloride, is easier to clean up, and

doesn't stain. Etching

Place the PCB in the etch tank. The etch tank is a tall, thin tank

that contains the etching chemical. Common etching chemicals include

Ferric Chloride and Ammonium Persulfate. The tank also contains a

heater and bubbler. The bubbler pumps air through the tank to

agitate the chemicals to speed up the etching process. Etching

typically requires 3-5 minutes with a fresh, heated solution. TIP

- Ammonium Persulfate is a clear etching chemical that produces

less caustic vapors than Ferric Chloride, is easier to clean up, and

doesn't stain.

|

|

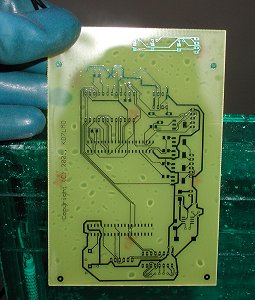

PCB

in etch tank and after etching process is complete.

Tin Plating

After

etching, the ink left on the board is removed with a solvent such as MEK

or Acetone. The exposed copper is protected by placing the board in

a tinning solution or Fluoboric Acid. The solution will cause the

copper to change colors to a silver or tin color. Tinning improves

the solder ability of the board, prevents copper oxidation, and gives the

PCB a finished appearance. Tin Plating

After

etching, the ink left on the board is removed with a solvent such as MEK

or Acetone. The exposed copper is protected by placing the board in

a tinning solution or Fluoboric Acid. The solution will cause the

copper to change colors to a silver or tin color. Tinning improves

the solder ability of the board, prevents copper oxidation, and gives the

PCB a finished appearance.

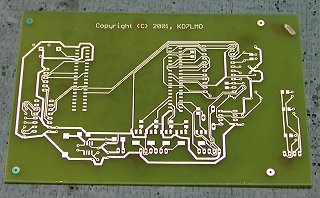

PCB after tinning.

Drilling /

Sizing The

final step to creating the PCB is drilling holes for mounting the through

hole components and connectors. The use of surface mount components

greatly simplifies the final construction of a PCB. In addition,

surface mount components allow for smaller designs, elimination of

potential socket failures, and a wider selection of components. Drilling /

Sizing The

final step to creating the PCB is drilling holes for mounting the through

hole components and connectors. The use of surface mount components

greatly simplifies the final construction of a PCB. In addition,

surface mount components allow for smaller designs, elimination of

potential socket failures, and a wider selection of components.

|