|

|

PCB

- Printed Circuit Board

A PCB, or Printed Circuit Board, offers a number of advantages over wire

wrapped or perf board assembly. The PCB allows the use of fine pitch,

surface mount components, a smaller footprint, more rugged assembly, ease

of duplication, and a

more professional final product. The

following is a step-by-step guide to creating a PCB using a positive,

photo resist process. An entire kit consisting of pre-sensitized PCBs,

chemicals, UV lamp, and etching tank is available from MG

Chemicals. The kit is also available through distributors such

as Mouser

and Digi-Key.

Safety

It should go without saying, but I'll say it anyway, this stuff can be

dangerous. Making PCBs requires chemicals that are heated, UV light,

and sharp cutting tools. At a minimum, wear rubber gloves, safety glasses

or a face shield, and work in a well ventilated area. Safety

It should go without saying, but I'll say it anyway, this stuff can be

dangerous. Making PCBs requires chemicals that are heated, UV light,

and sharp cutting tools. At a minimum, wear rubber gloves, safety glasses

or a face shield, and work in a well ventilated area.

Create the

PCB layout The Eagle schematic capture, PC board layout, and auto router

application is utilized

to created the project PCBs. The software package is available from CadSoft.

CadSoft offers a freeware version of the tool for Windows and Linux as

well as professional versions at a very reasonable cost. After the

printed circuit board layout is generated, it is printed on a overhead

projector transparency. A box of transparency sheets for laser or

inkjet printers are available at most office supply stores. TIP - When printing

on the transparency,

select the highest resolution and darkest print option on your printer to

create dense trace lines. Create the

PCB layout The Eagle schematic capture, PC board layout, and auto router

application is utilized

to created the project PCBs. The software package is available from CadSoft.

CadSoft offers a freeware version of the tool for Windows and Linux as

well as professional versions at a very reasonable cost. After the

printed circuit board layout is generated, it is printed on a overhead

projector transparency. A box of transparency sheets for laser or

inkjet printers are available at most office supply stores. TIP - When printing

on the transparency,

select the highest resolution and darkest print option on your printer to

create dense trace lines.

Sample PCB artwork.

Additional information on viewing the PCB artwork, PCB tools, and

component libraries is available in the

Technology section.

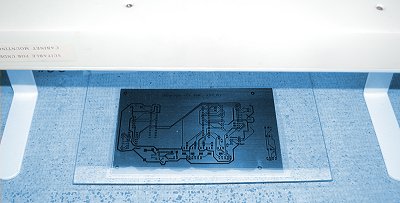

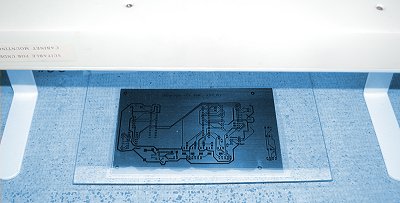

Expose the

Board After the PCB artwork is printed on the transparency, it is laid

on the pre-sensitized PCB. A pre-sensitized PCB has a layer of

green or blue ink that is sensitive to UV light. Any portion of the

ink that is exposed to the light will come off the board when placed in a

chemical developer bath. The exposure time for the MG Chemicals boards are 5

minutes. The quality of the board is effected by the exposure time,

so a stop watch is handy when exposing the board. TIP - To hold

the transparency sheet on the surface of the board, place a piece of glass

on top of the board. This will ensure the trace lines are sharp. Expose the

Board After the PCB artwork is printed on the transparency, it is laid

on the pre-sensitized PCB. A pre-sensitized PCB has a layer of

green or blue ink that is sensitive to UV light. Any portion of the

ink that is exposed to the light will come off the board when placed in a

chemical developer bath. The exposure time for the MG Chemicals boards are 5

minutes. The quality of the board is effected by the exposure time,

so a stop watch is handy when exposing the board. TIP - To hold

the transparency sheet on the surface of the board, place a piece of glass

on top of the board. This will ensure the trace lines are sharp.

PCB

exposure under UV light.

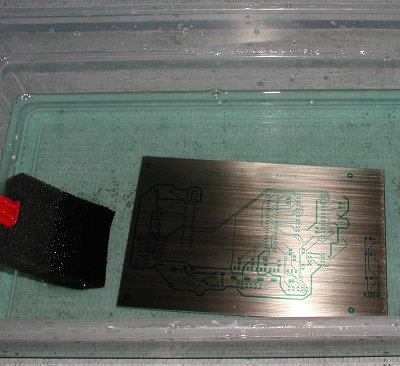

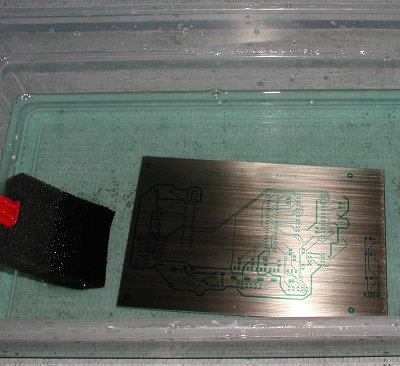

Develop

PCB Pattern After the PCB has been exposed to UV light it is placed in a

weak solution of developer or Sodium Hydroxide. Using a foam brush,

gently brush the surface of the board. The development cycle will

typically require 1 to 2 minutes to remove the ink that was exposed to UV

light. The unexposed ink will remain on the PCB. After

development, carefully inspect the traces and wash the board with water. TIP

- Warm the developer solution to 75-80°F before developing the

board. This will greatly accelerate the development cycle and

prevent the removal of narrow width traces in the extended development

time of a cold solution. Develop

PCB Pattern After the PCB has been exposed to UV light it is placed in a

weak solution of developer or Sodium Hydroxide. Using a foam brush,

gently brush the surface of the board. The development cycle will

typically require 1 to 2 minutes to remove the ink that was exposed to UV

light. The unexposed ink will remain on the PCB. After

development, carefully inspect the traces and wash the board with water. TIP

- Warm the developer solution to 75-80°F before developing the

board. This will greatly accelerate the development cycle and

prevent the removal of narrow width traces in the extended development

time of a cold solution.

PCB

development bath.

|